Imagine a construction site bustling with activity: cranes lifting heavy beams, workers maneuvering equipment, and the constant hum of machinery. This is a scene that plays out on countless projects around the world, but it also highlights the inherent risks associated with such endeavors. Ensuring the safety of everyone involved becomes paramount, demanding a comprehensive approach to project safety requirements and a steadfast commitment to zero tolerance towards unsafe practices.

Image: www.sketchbubble.com

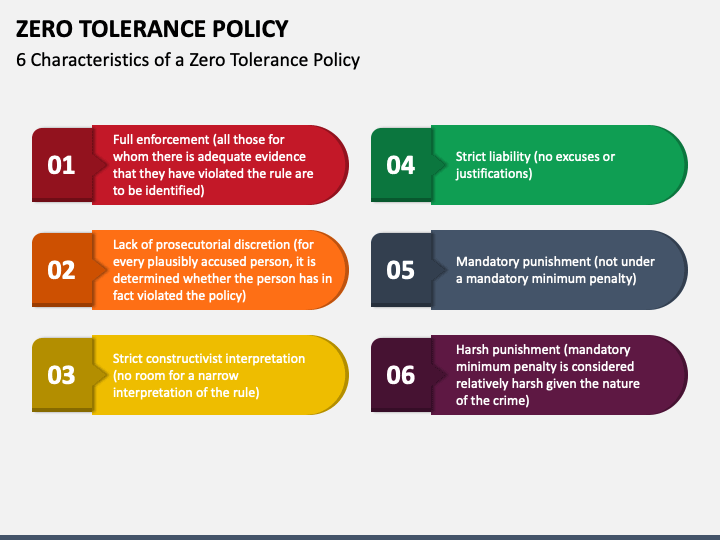

Project safety requirements, often enforced through strict protocols and regulations, define the minimum standards required to maintain a safe work environment. This includes comprehensive risk assessments, meticulous planning, and proactive measures to mitigate potential hazards. However, enforcing these requirements and achieving a true “zero tolerance” policy demands a culture of safety that permeates every aspect of the project. This commitment goes beyond mere compliance and hinges on the collective responsibility of every individual involved, from management to workers on the ground.

Understanding the “Why” Behind Safety Requirements

The Cost of Negligence:

The consequences of ignoring safety requirements can be devastating, both in terms of human lives and financial losses. Accidents, often preventable through proper planning and adherence to safety protocols, can result in:

- Fatalities and injuries: The most tragic outcome of workplace accidents is loss of life or permanent injuries, leaving families and communities devastated.

- Project delays and cost overruns: Accidents disrupt project timelines, leading to costly delays and impacting project budgets significantly.

- Legal liability and reputation damage: Violations of safety regulations can lead to fines, lawsuits, and damage to the organization’s reputation, impacting future projects and investor confidence.

In addition to these direct impacts, workplace accidents also have a profound effect on the psychological well-being of employees and the overall morale of the team. The fear of injury or the shock of witnessing an accident can create a climate of anxiety and distrust, impacting productivity and hindering team cohesion.

The Ethical Imperative:

Beyond the tangible costs, there is a fundamental ethical obligation to prioritize safety at every stage of a project. Every employee has the right to a safe and healthy work environment, and it is the responsibility of management to ensure that these rights are not compromised. A “zero tolerance” policy signifies a commitment to putting the well-being of people above profit or productivity, a core value that should guide every decision and action taken on a project.

Image: www.slideserve.com

The Pillars of Project Safety Requirements

1. Risk Assessment: A Proactive Approach

Risk assessment forms the foundation of any effective safety program. It involves identifying potential hazards, evaluating their severity, and determining the likelihood of their occurrence. This process typically involves:

- Hazard identification: This involves a thorough review of the project’s specific environment, operations, and potential hazards, including those related to equipment, materials, workplace design, and the work procedures themselves.

- Risk analysis: Once hazards are identified, their potential severity and likelihood of occurrence are assessed. This involves considering factors like the probability of the hazard materializing, the potential consequences, and the availability of preventive measures.

- Risk evaluation and control: Based on the risk analysis, appropriate control measures are implemented to mitigate the risks. This might include using Personal Protective Equipment (PPE), modifying work procedures, implementing engineering controls, or implementing safety training programs.

The results of risk assessments should be documented, regularly reviewed, and updated as the project progresses. This ensures that the safety plan remains relevant and adapts to changing conditions or unforeseen hazards.

2. Safety Training and Education: Empowering Individuals

Safety training is not a one-off event, but a continuous process that empowers individuals to identify potential hazards, understand safety procedures, and take appropriate precautions. Effective training programs should include:

- General safety awareness: This introduces basic safety principles, including the importance of wearing PPE, reporting hazards, and following company safety protocols.

- Job-specific safety training: Tailored to the specific tasks and equipment used on a project, this ensures workers understand the associated risks and appropriate safety precautions.

- Emergency preparedness: Training on emergency procedures, including evacuation plans, first aid, and the use of emergency equipment.

- Hazard communication: Training on understanding and communicating information on hazardous materials, including material safety data sheets (MSDS) and appropriate handling procedures.

Regular refresher courses and ongoing safety updates are crucial to keep workers informed about changes in regulations, evolving best practices, and updated safety procedures.

3. Personal Protective Equipment (PPE): The Last Line of Defense

PPE serves as the final layer of protection for workers exposed to potential hazards. The selection of suitable PPE is critical and should be based on the identified risks. Commonly used PPE includes:

- Head protection: Hard hats provide protection from falling objects or impacts.

- Eye protection: Safety glasses, goggles, or face shields protect eyes from debris, chemicals, or radiation.

- Hearing protection: Earplugs or earmuffs protect against excessive noise levels.

- Respiratory protection: Respirators are used in environments with hazardous air contaminants.

- Hand protection: Gloves protect hands from cuts, abrasions, chemicals, or temperature extremes.

- Foot protection: Safety boots with steel toes or puncture-resistant soles prevent foot injuries.

PPE must be regularly inspected, maintained, and replaced as needed to ensure its effectiveness. Workers must be instructed on the proper use and limitations of specific PPE, as well as the proper procedures for its storage and cleaning.

4. Incident Reporting and Investigation: Learning from Mistakes

A “zero tolerance” policy necessitates a culture where incidents, even near misses, are reported promptly and investigated thoroughly. This provides valuable insights into the root causes of unsafe conditions or practices and enables proactive steps to prevent similar incidents in the future.

An effective incident reporting system should:

- Encourage reporting: Create a safe environment for employees to report incidents without fear of retribution or disciplinary action.

- Collect comprehensive information: Gather detailed information about the incident, including time, location, events leading up to the incident, witnesses, and any injuries or damage.

- Thorough investigation: Analyze the incident to determine the root causes, identify contributing factors, and assess the effectiveness of existing safety procedures.

- Implement corrective actions: Based on the investigation’s findings, implement corrective actions to mitigate the risks and prevent recurrence.

- Continuous improvement: Regularly review incident data to identify trends, evaluate the effectiveness of safety programs, and identify areas for further improvement.

Zero Tolerance: A Mindset, Not Just a Policy

Enforcing a “zero tolerance” policy towards unsafe practices goes beyond simply writing rules. It requires a shift in mindset and a strong commitment to building a culture of safety where everyone feels empowered to take an active role in ensuring their own safety and the safety of their colleagues.

Leading by Example:

Senior management plays a critical role in fostering a culture of safety. Leaders must demonstrate a genuine concern for worker well-being, actively participate in safety programs, and promote a “safety first” mentality throughout the organization. Their actions and decisions should consistently reflect the importance of safety and reinforce the “zero tolerance” policy.

Employee Empowerment:

Every employee has a responsibility to contribute to a safe work environment. Encouraging workers to identify hazards, report unsafe situations, and participate in safety discussions, is crucial to building a proactive safety culture. Providing regular safety training, emphasizing the importance of hazard communication, and fostering open communication about safety concerns empowers employees to play a vital role in preventing accidents and fostering a safe workplace.

Continuous Improvement:

Safety is not a static endpoint, but an ongoing journey of learning and improvement. Regular review of safety procedures, incident data analysis, and participation in industry best practices workshops ensure that safety programs are continually evolving to meet the changing demands of the project and the industry as a whole. This commitment to continuous improvement signals a dedication to building a safe and healthy work environment for everyone involved.

An Explanation Of The Project Safety Requirements And Zero Tolerance

Conclusion

Implementing comprehensive project safety requirements and establishing a strong “zero tolerance” policy towards unsafe practices is not simply a legal obligation, but a moral imperative. It is a commitment to protecting the lives and well-being of everyone involved in the project. By fostering a culture of safety, prioritizing risk mitigation, investing in training, and empowering employees to actively participate in safeguarding their workplace, we can create a work environment where every individual can contribute to a successful project without compromising their health and safety. This is the foundation for a safe and healthy work environment – a foundation built on responsibility, respect, and the unwavering commitment to zero tolerance towards unsafe practices.