Have you ever wondered what goes into ensuring the safety of the pressure vessels used in power plants, chemical processing facilities, and countless other industrial applications? The answer lies in a document known as the ASME Section VIII Division 1, an essential resource for engineers, designers, and manufacturers involved in the world of pressure vessel construction. This comprehensive code sets the standards for design, fabrication, inspection, and testing, laying the groundwork for reliable and safe equipment that underpins countless industries.

Image: dokumen.tips

Think of your local water treatment plant, where massive pressure vessels hold and treat your water supply. Or consider the industrial giants that rely on pressure vessels to synthesize vital chemicals or refine fuels. The ASME Section VIII Division 1 PDF is the backbone of these operations, dictating the rules and regulations that ensure these structures can handle the immense pressures and temperatures they encounter without compromising safety. In this article, we delve into the world of ASME Section VIII Division 1, exploring its history, key components, and the profound impact it has on our lives.

A Legacy of Safety: The Origins of ASME Section VIII Division 1

The ASME Section VIII Division 1 code wasn’t born overnight. Its history is intricately interwoven with the evolution of pressure vessel technology itself. Driven by the need for standardized and safe practices in the early 20th century, the American Society of Mechanical Engineers (ASME) took on the crucial task of developing a comprehensive set of rules for pressure vessel design. The result was ASME Section VIII, initially comprised of a single division.

As pressure vessel technology advanced, the need for a more specialized set of rules for different types of vessels became apparent. In 1959, ASME Section VIII was split into two divisions: Division 1 and Division 2. Division 1 focused on providing a comprehensive code for the majority of pressure vessels, encompassing a wide range of industries and applications. Division 2, on the other hand, addressed the needs of more specialized vessels, often employed in extreme environments and demanding specific design considerations.

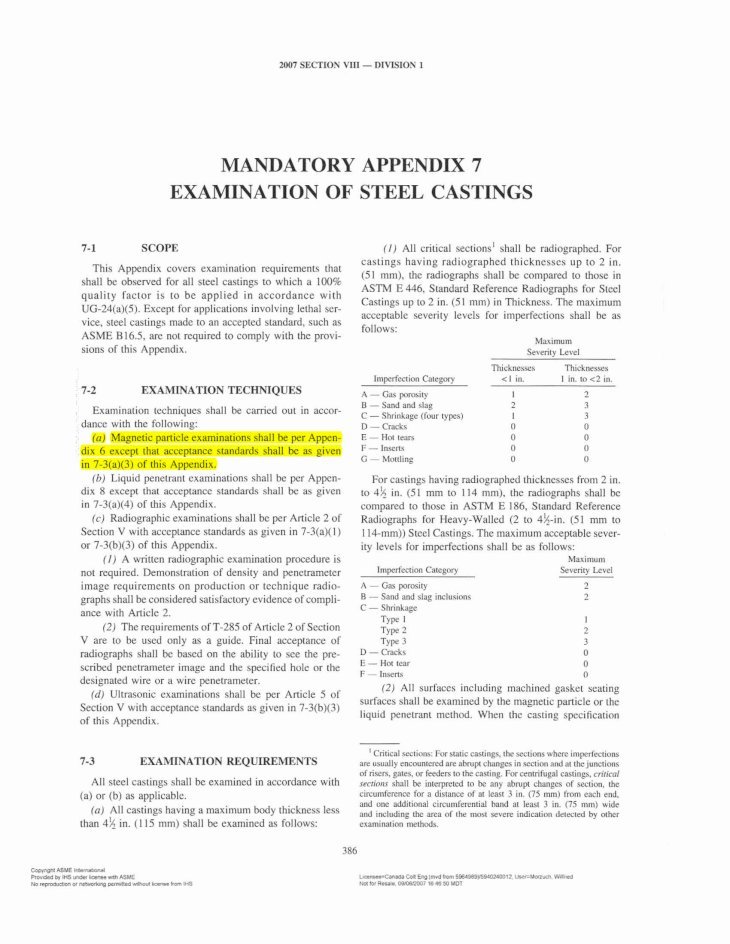

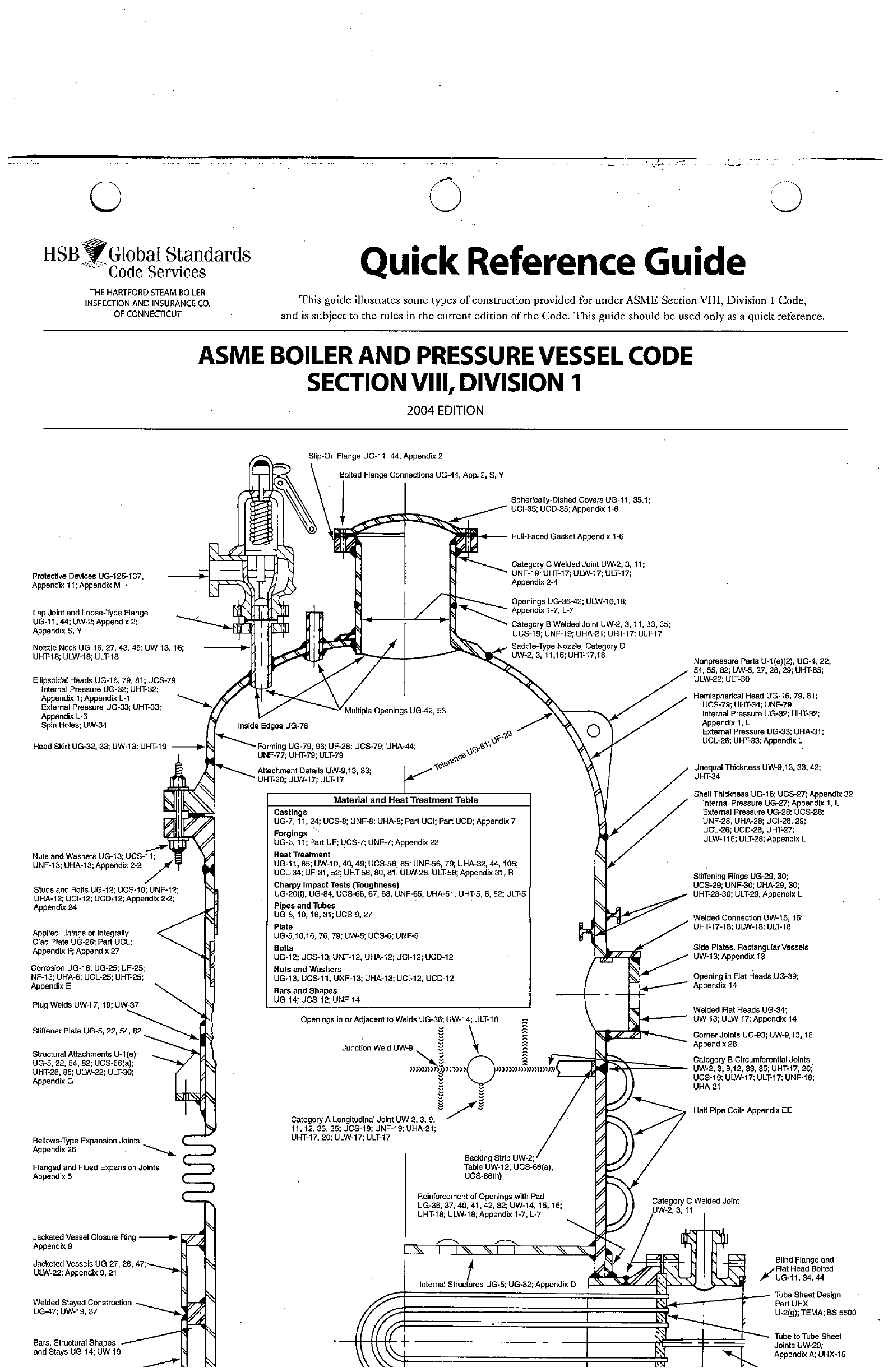

The Blueprint for Safety: Understanding the Structure of ASME Section VIII Division 1

The ASME Section VIII Division 1 PDF is more than just a collection of rules and regulations; it’s a carefully crafted blueprint that guides every step of the pressure vessel creation process. The code is structured into various sections, each focusing on a specific aspect of design, fabrication, and inspection. Understanding this structure is key to unlocking the full potential of the code.

- General Requirements (Part UG): These initial sections provide a fundamental overview of the code’s scope and definitions, setting the stage for the detailed rules to follow.

- Materials (Part UA): The code outlines permissible materials for pressure vessel construction, ensuring the use of materials that can withstand the intended pressures and temperatures. Various materials like carbon steel, stainless steel, and non-ferrous metals are meticulously analyzed and categorized for suitability.

- Design (Part U-2): This section is the heart of the code, laying out specific rules for the design of pressure vessel components. From shell thickness calculations to the design of openings and attachments, the code meticulously addresses every detail to ensure structural integrity. This section is often the most complex and requires a deep understanding of engineering principles.

- Fabrication (Part UW): Fabrication is where the design takes shape. This section outlines the acceptable methods and procedures for the fabrication of pressure vessels. Welding techniques, heat treatments, and inspections are all meticulously described, ensuring that every step in the fabrication process contributes to the overall safety and integrity of the vessel.

- Inspection (Part UI): Once the vessel is fabricated, it undergoes rigorous inspection to ensure compliance with the code. This section specifies the methods and criteria for inspecting the vessel, including visual inspections, non-destructive testing, and pressure tests. The inspection process serves as a final verification of the vessel’s quality and safety.

Beyond the Code: The Importance of ASME Section VIII Division 1 Certification

The ASME Section VIII Division 1 code isn’t just about reading through a document; it’s about adhering to strict standards and ensuring that the design, fabrication, and inspection processes are executed with meticulous precision. To demonstrate this adherence, pressure vessel manufacturers often seek ASME Section VIII Division 1 certification. This certification signifies that the manufacturer has demonstrated their ability to produce vessels that comply with the code’s rigorous requirements.

The certification process involves a comprehensive evaluation of the manufacturer’s facilities, equipment, procedures, and personnel. It ensures that the manufacturer has a thorough understanding of the code, implements the specified fabrication practices, and adheres to strict quality control measures. Achieving this certification often involves periodic audits and inspections, reaffirming the ongoing commitment to safety and quality.

Image: lasopapro935.weebly.com

Beyond the Pages: Real-World Applications of ASME Section VIII Division 1

The impact of ASME Section VIII Division 1 extends far beyond the pages of the code, touching virtually every aspect of our lives. From the power plants that generate our electricity to the refineries that process our fuels, the code’s influence is profound.

Think of the pressure vessels that store and transport natural gas, ensuring a reliable source of energy for millions of homes and businesses. Or consider the reactors in chemical plants, where crucial reactions take place under controlled pressure and temperature conditions, thanks to the meticulous design standards outlined in the code. The code ensures that these vessels, handling potentially hazardous substances under extreme conditions, operate safely and reliably, safeguarding our communities and industries.

Unlocking the Power of the Code: Practical Tips for Engineers and Manufacturers

For engineers and manufacturers working with pressure vessels, understanding and adhering to ASME Section VIII Division 1 is crucial. Here are some key takeaways that can empower you to leverage the code effectively:

- Seek Continuous Education: The code is constantly updated to address new technological advancements and evolving safety standards. Stay current with the latest revisions and updates to ensure your knowledge remains relevant.

- Focus on Collaboration: Working closely with inspectors, designers, and fabricators throughout the pressure vessel lifecycle fosters a collaborative environment, ensuring seamless integration of the code’s requirements.

- Embrace Design Optimization: The code doesn’t just limit; it provides a framework for design optimization, ensuring that vessels are sufficiently robust while minimizing material usage and production costs.

- Leverage Digital Tools: Digital tools, such as design software and inspection platforms, can enhance efficiency and accuracy when working with ASME Section VIII Division 1.

Asme Section 8 Division 1 Pdf

Conclusion: A Foundation for Safety and Innovation

The ASME Section VIII Division 1 PDF stands as a testament to the dedication and commitment of engineers and manufacturers to prioritize safety in the realm of pressure vessel technology. It’s a resource that empowers designers to create reliable and robust vessels. By adhering to its stringent standards, we ensure the safety of countless industrial processes, safeguarding our communities, and driving innovation in industries that touch every aspect of our lives. The code’s evolution continues, reflecting advancements in technology and a constant pursuit of improved safety standards. As we move forward, the legacy of ASME Section VIII Division 1 will remain a cornerstone of responsible pressure vessel design and fabrication, ensuring the safe and reliable operation of critical infrastructure around the world.