Have you ever wondered what those numbers on your chiller’s pressure gauges mean and why they are so crucial to its operation? The answer lies in understanding the role of R134a refrigerant and its pressure fluctuations within the chilling system. Decoding the pressure readings on your chiller’s suction and discharge lines acts like a secret code that reveals the health and efficiency of your cooling system.

Image: owendale.z21.web.core.windows.net

R134a is an extremely popular refrigerant due to its environmentally friendly nature and widespread use in chillers. Understanding the pressure readings on a chiller using R134a allows technicians and operators to monitor system performance, detect potential issues, and ensure the efficient operation of the chiller. This knowledge is crucial for optimizing energy consumption, extending the lifespan of the system, and preventing costly breakdowns. Let’s delve into the world of R134a suction and discharge pressure to unravel these mysteries and empower you with critical knowledge.

Getting to the Heart of the Matter: R134a and the Chilling Process

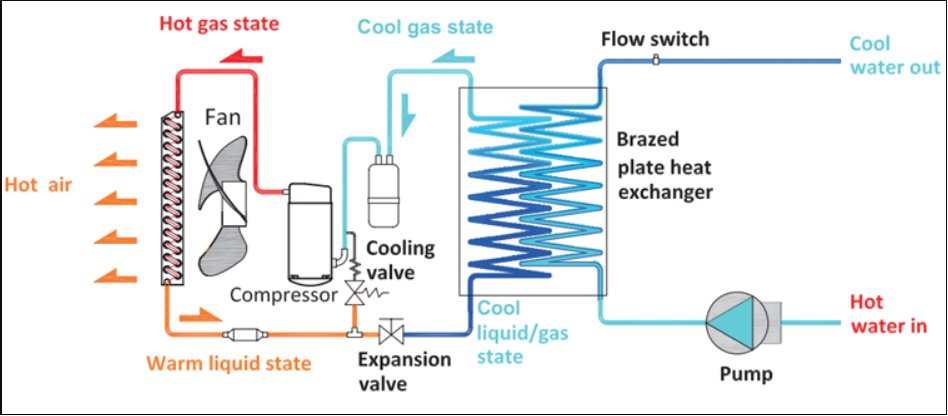

To grasp the importance of suction and discharge pressure, we first need to comprehend the basic functioning of a chiller. The whole process revolves around the refrigerant’s journey within the chiller. R134a’s state continually evolves between a liquid and a gas, and it’s this change that drives the cooling process. Imagine R134a as a tireless worker, carrying thermal energy away from the chilling system.

At the heart of the chiller is the compressor, which plays the role of an energetic pump. This pump compresses the R134a, raising its temperature and pressure. The now hot and pressurized refrigerant flows through the condenser, where it sheds its heat to the surrounding environment. This release of heat is what actually cools the intended space. As R134a releases heat, it transforms back into a liquid state, still at high pressure.

Suction and Discharge: The Twin Indicators of Chiller Health

In the next stage, the liquid refrigerant travels through the expansion valve, where it undergoes a rapid drop in pressure. This sudden pressure drop leads to a drop in temperature, making the refrigerant extremely cold. The super-cooled R134a then flows through the evaporator, where it readily absorbs heat from the chilled water or air. This heat absorption is the heart of the cooling process, taking thermal energy from the environment that needs to be cooled.

The suction line carries the cold refrigerant, at low pressure, directly to the compressor. The discharge line carries the hot compressed refrigerant to the condenser to release the absorbed heat. How these pressure readings evolve on the suction and discharge lines tell the story of your chiller’s health. They are the critical indicators of refrigerant flow, system pressures, and overall efficiency.

Decoding the Pressure Readings: What They Tell Us

High discharge pressure is usually a sign of overheating inside the compressor. This can be caused by issues like refrigerant overcharge, a clogged condenser, or a failing compressor. If the chiller struggles to compress the refrigerant due to these problems, it will exert more effort, resulting in higher discharge pressure. Conversely, low discharge pressure could indicate a refrigerant leak, compressor malfunction, or even a blocked discharge line.

On the other hand, low suction pressure can signal problems like a refrigerant leak, undercharge, or an issue with the expansion valve. An inadequate amount of refrigerant in the system will cause lower pressure throughout the cycle, decreasing the cooling capacity. High suction pressure can be a sign that the system is overloaded or that there is a blockage in the suction line hindering the refrigerant flow.

Image: hexoninstruments.com

Understanding the Pressure Readings: A Key to Effective Chiller Maintenance

Monitoring suction and discharge pressure readings is essential for preventive maintenance and troubleshooting. If you notice deviations from expected readings, investigate the cause immediately. Early detection and diagnosis of pressure issues can prevent major system breakdowns and ensure a long lifespan for your chiller. Pressure readings provide insights into the chiller’s performance.

Beyond the Numbers: Analyzing Pressure Trends

While the absolute pressure readings provide a snapshot of the system’s status, observing trends over time is even more insightful. A gradual decline in suction pressure over time might indicate a slow refrigerant leak. A sharp increase in discharge pressure might suggest a sudden change in the compressor’s performance. Consistent readings outside the normal range warrants further investigation to identify the underlying causes.

A Practical Guide to Analyzing Pressure Readings

To understand the normal pressure readings for your specific chiller, consult the manufacturer’s specifications. These guidelines provide the ideal operating ranges for suction and discharge pressure, allowing you to identify any deviations from the normal parameters. Additionally, you can use a pressure-temperature chart for R134a to determine the expected pressure readings based on the refrigerant’s temperature and operating conditions.

The Importance of Professional Expertise

While this information provides a basic understanding of R134a suction and discharge pressure, it’s crucial to remember that operating and maintaining chillers requires specialized knowledge and experience. Consult with a qualified HVAC technician or refrigeration specialist for any issues or concerns regarding your chiller. They possess the expertise to diagnose problems, perform maintenance tasks, and ensure your chiller is operating optimally.

R134a Suction And Discharge Pressure In Chiller

Conclusion: Empowering You with Knowledge

By understanding the interconnectedness of R134a suction and discharge pressure, you gain valuable insights into the health and efficiency of your chiller system. This knowledge empowers you to make informed decisions about maintenance, troubleshoot issues promptly, and ensure the optimal performance of your chiller. Remember to regularly monitor pressure readings, use professional expertise for any repairs or adjustments, and keep your chiller operating at peak performance for years to come.