Imagine a powerful truck roaring down a highway, hauling a heavy load. That engine, churning away with impressive force, likely operates on a diesel cycle. This cycle, named after Rudolf Diesel, is a thermodynamic marvel that defines how internal combustion engines transform fuel into energy. Understanding its workings involves visualizing the cycle’s journey through pressure-volume (P-V) and temperature-entropy (T-S) diagrams – intricate graphical representations that reveal the engine’s key characteristics. Today we delve into these diagrams to unveil the mysteries of the diesel cycle.

Image: www.researchgate.net

These diagrams, far from being just academic exercises, hold practical applications. They help engineers design efficient engines, optimize fuel consumption, and assess performance. By understanding how the engine operates at various stages – compression, combustion, expansion, and exhaust – engineers can fine-tune its design and improve its efficiency and environmental impact.

Dissecting the Diesel Cycle: P-V & T-S Diagrams

The Pressure-Volume (P-V) Diagram: A Visual Story of Work and Heat

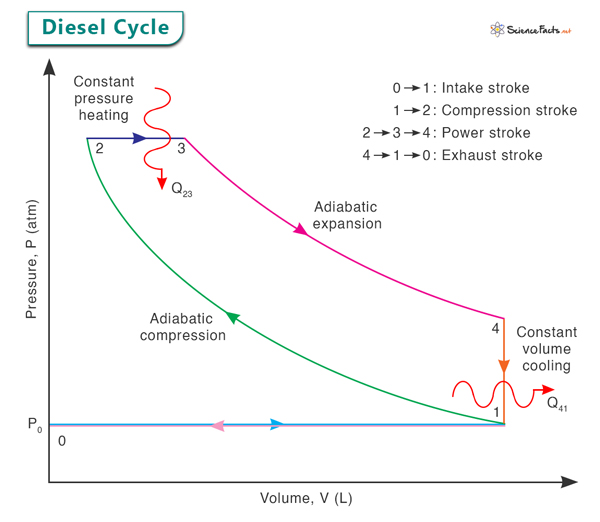

The P-V diagram plots pressure against volume, mapping out the engine cycle’s journey. Each point on the curve represents the state of the air-fuel mixture within the cylinder at a specific moment. The area enclosed by the loop represents the net work produced during one cycle. Let’s break down the stages:

- Intake: The cycle starts with air intake, depicted as a horizontal line on the P-V diagram. Pressure remains constant as the cylinder fills with air.

- Adiabatic Compression: Next, the piston compresses the air, raising its pressure and temperature. This is represented by a rising curve on the diagram, with no heat exchange with the surroundings (adiabatic). It’s during this compression that diesel engines differ significantly from gasoline engines. Diesel engines compress the air to a much higher pressure, resulting in a higher temperature.

- Combustion: Fuel is injected into the hot, compressed air. It ignites due to the high temperature, leading to rapid combustion. This is portrayed as a vertical line on the P-V diagram, signifying constant volume and a sharp increase in pressure.

- Adiabatic Expansion: The hot combustion gases expand, pushing the piston down and generating power. On the P-V diagram, this is depicted by a decreasing curve, again with no heat exchange (adiabatic).

- Exhaust: Finally, exhaust gases are expelled from the cylinder, represented by a horizontal line at constant pressure. The cycle concludes, ready to start anew.

The Temperature-Entropy (T-S) Diagram: Tracking Energy Flow

The T-S diagram, like the P-V diagram, tells the story of the engine cycle, but through a different lens. It maps temperature against entropy, a measure of energy dispersal or disorder. This diagram reveals not only the temperature changes but also the energy flow, enabling a deeper understanding of the cycle’s thermodynamic efficiency.

- Intake and Compression: These phases are similar to the P-V diagram, showing a rising temperature as the air is compressed. On the T-S diagram, this is represented as a diagonal line.

- Combustion: The rapid combustion increases temperature and entropy, depicted as a horizontal line on the T-S diagram. The area under this line represents the heat added during combustion.

- Expansion and Exhaust: Cooling and entropy reduction occur as the gases expand and exhaust, represented by diagonal lines on the T-S diagram.

Image: www.sciencefacts.net

Optimizing Engine Efficiency: The Role of Compression Ratio

One of the key aspects of diesel engine design is the compression ratio. This ratio, calculated as the volume of the cylinder when the piston is at its lowest point (bottom dead center) divided by the volume when the piston is at its highest point (top dead center), directly influences engine efficiency. Higher compression ratios lead to higher temperatures during compression, making it easier to ignite the fuel, resulting in higher efficiency and lower fuel consumption. However, this comes with the challenge of dealing with higher pressures and temperatures, requiring robust engine components to withstand these demanding conditions.

Modern Trends in Diesel Engine Technology

Diesel engines are constantly evolving to meet ever-increasing environmental standards and improve fuel efficiency. Recent developments include:

- Selective Catalytic Reduction (SCR): This technology reduces harmful nitrogen oxides (NOx) emissions. An SCR system injects a reducing agent like urea into the exhaust stream, converting NOx into harmless nitrogen and water.

- Diesel Particulate Filters (DPF): These filters trap soot particles from the exhaust stream, significantly reducing particulate matter emissions.

- Variable Geometry Turbochargers (VGT): These turbochargers adjust the flow of exhaust gases to optimize engine performance and fuel efficiency across different operating conditions.

- Hybrid Diesel Engines: Combining a diesel engine with an electric motor, hybrid systems enhance fuel efficiency, providing additional power during acceleration and reducing emissions.

Tips for Optimizing Diesel Engine Performance

Here are some tips to keep your diesel engine running smoothly and efficiently:

- Regular Maintenance: Regular oil changes, air filter replacements, and fuel filter cleanings are essential to prevent wear and tear and ensure optimal performance.

- High-Quality Fuel: Using fuel specifically designed for diesel engines is crucial for maintaining engine performance and longevity. Contaminants in fuel can lead to engine problems and reduced efficiency.

- Proper Combustion: Regular tune-ups are important to ensure proper fuel injection and combustion. This helps optimize fuel economy and reduce emissions.

- Driving Habits: Driving smoothly, avoiding aggressive acceleration and braking, and using cruise control when possible can contribute to better fuel economy.

Why These Tips Matter:

These tips may seem simple, but they have a significant impact on the longevity and efficiency of your diesel engine. Regular maintenance prevents premature wear and tear, while using high-quality fuels and optimizing combustion ensure that your engine runs smoothly and efficiently, maximizing fuel economy and reducing emissions. Proper driving habits minimize unnecessary fuel consumption and contribute to a healthier environment.

Frequently Asked Questions (FAQ)

Q: What are the advantages of a diesel engine?

A: Diesel engines offer several advantages, including:

- Higher Fuel Efficiency: Diesel engines achieve better fuel economy compared to gasoline engines, especially under heavy loads.

- Increased Torque: Diesel engines generate a higher amount of torque at low RPM, making them ideal for heavy-duty applications.

- Durability: Diesel engines are known for their robustness and long lifespan.

Q: What are the disadvantages of a diesel engine?

A: While diesel engines offer advantages, they also have some drawbacks, including:

- Higher Initial Cost: Diesel engines are usually more expensive to purchase than gasoline engines.

- Emissions: Diesel engines can produce higher levels of particulate matter and NOx emissions compared to gasoline engines.

- Noise: Diesel engines tend to be noisier than gasoline engines.

Q: How do diesel engines compare to gasoline engines?

A: Both diesel and gasoline engines function on the principles of internal combustion but differ in their fuel ignition methods. Gas engines use spark plugs to ignite the fuel, while diesel engines rely on compression heating to ignite fuel. This difference in ignition leads to distinct characteristics, with diesel engines offering higher torque and efficiency, while gasoline engines tend to be more responsive and less expensive.

Diesel Cycle P-V And T-S Diagram

https://youtube.com/watch?v=qU2ehVIpdUQ

Conclusion

The diesel cycle, with its intricate P-V and T-S diagrams, is a captivating journey through the world of engine mechanics. These diagrams provide a visual roadmap of energy transformation, revealing the cycle’s inner workings. Furthermore, understanding diesel engine design and optimization, including the role of compression ratio, is crucial for developing efficient and environmentally friendly engines. By embracing modern technologies and adopting best practices, we can maximize diesel engine performance while minimizing their environmental impact. Are you interested in learning more about diesel engine technology and its latest advancements?