Imagine working in a hazardous environment, unaware of the invisible threats lurking in the air. It’s a terrifying thought, and it’s the reality for many workers in industries like manufacturing, construction, and oil and gas. That’s why reliable gas detectors are essential for safety. But even the most sophisticated equipment needs regular calibration to ensure accurate readings. This is where the XNX gas detector calibration 2022 PDF comes in. It’s not just a document; it’s a crucial tool to ensure safe working conditions and safeguard lives.

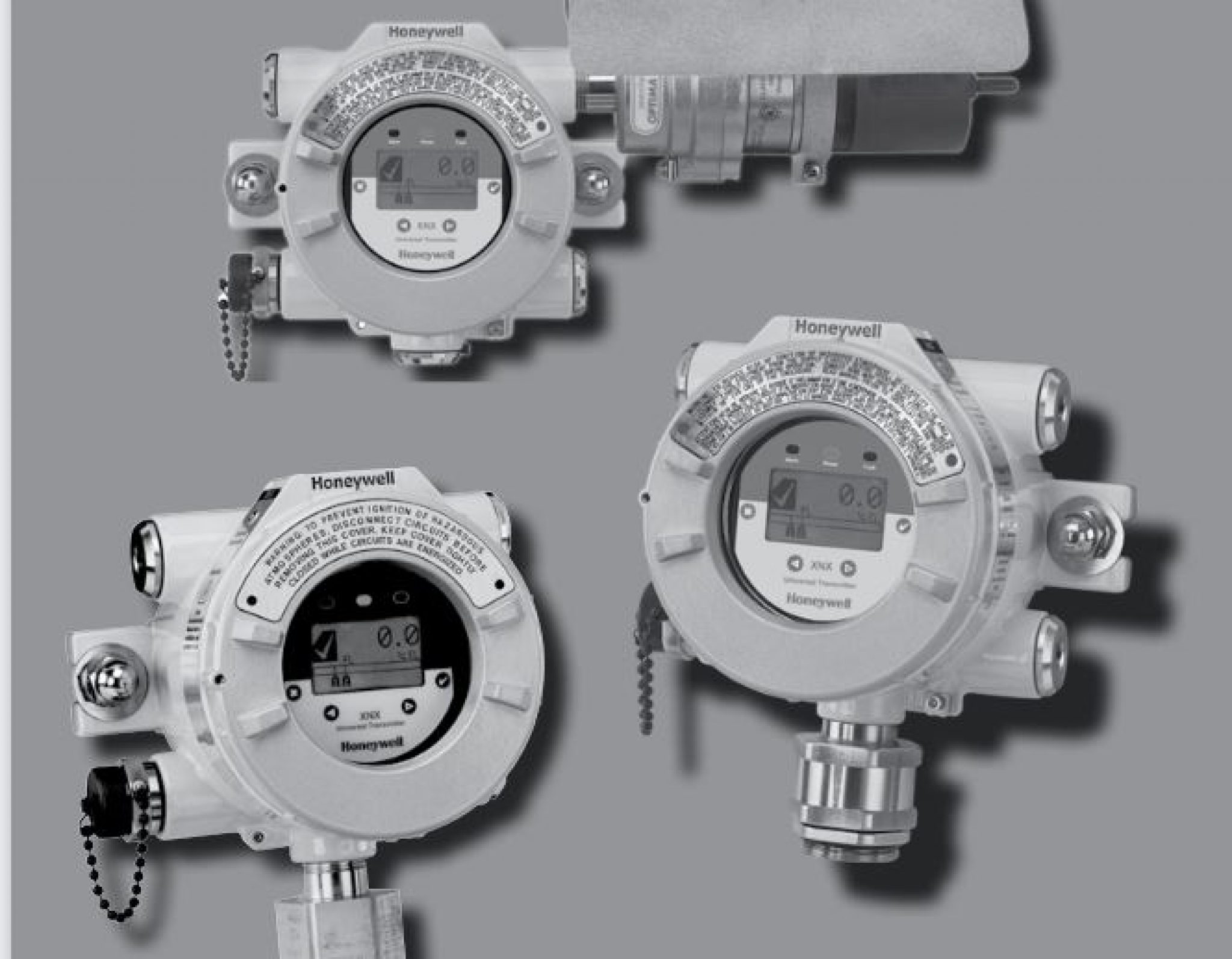

Image: admin.itprice.com

In 2022, the need for precise gas detection has become even more vital due to evolving safety regulations and the increasing awareness of the dangers of hazardous gases. The XNX calibration PDF provides a clear roadmap for calibrating your equipment to the latest standards, ensuring it reliably identifies and measures dangerous gases in various environments.

Understanding Gas Detector Calibration

Gas detector calibration is a vital procedure that involves adjusting the sensor’s response to accurately measure specific gas concentrations. It’s like calibrating a measuring scale to ensure it accurately displays the weight of an object. Just as a faulty scale can lead to inaccurate measurements, a miscalibrated gas detector can provide false readings, potentially leading to dangerous situations.

Calibration involves exposing the detector to known concentrations of the target gas. The detector’s response is then compared to the known concentration, and any adjustments are made to ensure accurate readings. This process is crucial for maintaining the accuracy and reliability of your gas detectors, ensuring they can effectively detect and alert workers to potentially dangerous gas levels.

The Importance of the XNX Gas Detector Calibration 2022 PDF

The XNX gas detector calibration 2022 PDF serves as a comprehensive guide for calibrating gas detectors. It covers various aspects of the process, from selecting the right calibration gas to performing the calibration steps correctly. By adhering to the instructions outlined in this PDF, you can ensure the accuracy and reliability of your gas detectors and maintain a safe working environment.

The 2022 update reflects the latest industry standards and best practices for gas detector calibration. It incorporates any changes in regulations or advancements in calibration techniques, ensuring your equipment meets the highest safety standards. This document is a valuable resource for anyone responsible for maintaining gas detectors, helping to prevent accidents, protect workers, and maintain compliance.

XNX Calibration Process: A Step-by-Step Guide

Image: priceinbangladesh.com

Step 1: Preparation

Begin by gathering all the necessary equipment, including the XNX gas detector, the calibration gas cylinder, and the calibration station. Ensure the gas detector is clean and free of any debris. Familiarize yourself with the calibration procedure outlined in the PDF and follow the safety precautions diligently.

Step 2: Selecting the Calibration Gas

The calibration gas should match the type of gas the detector is designed to detect. The XNX calibration PDF will specify the correct calibration gas for your specific gas detector. Ensure the gas cylinder is compatible with the detector and properly labeled.

Step 3: Setting Up the Calibration Station

Use a designated calibration station to control the flow of calibration gas. The station should be properly ventilated, with adequate safety measures in place. Connect the gas detector to the calibration station and ensure it is properly sealed.

Step 4: Calibrating the Detector

Follow the calibration instructions outlined in the XNX PDF. This will involve exposing the detector to a known concentration of the target gas and adjusting the detector’s response accordingly. The calibration procedure will vary depending on the specific gas detector model.

Key Tips for Effective Gas Detector Calibration

Calibration might seem straightforward, but there are some key points to remember for optimal results:

- Use fresh calibration gas: Outdated or contaminated calibration gas can compromise the accuracy of the calibration process. Ensure the gas cylinder is within its expiry date and has been stored properly.

- Follow the prescribed calibration interval: The manufacturer’s recommendations for calibration intervals should be strictly adhered to. This ensures the detector maintains optimal performance and accuracy.

- Document all calibration activities: Maintaining accurate records of calibration dates, gas used, and any adjustments made is essential for tracking the detector’s performance and compliance.

- Ensure proper training: Those responsible for calibrating gas detectors should receive adequate training on the procedure, ensuring they understand the process and can handle the equipment safely.

Expert Advice: Optimizing Your Calibration Routine

Calibration is not just a one-time event; it’s an ongoing process to ensure the ongoing accuracy of your gas detectors. Here are a few expert tips for optimizing your calibration routine:

1. Consider Bump Testing: Complement your regular calibration procedures with “bump testing” on a daily or weekly basis. This involves exposing the detector to a small concentration of gas to confirm its functionality. While bump testing doesn’t replace full calibration, it provides a quick check for potential issues.

2. Implement a Maintenance Schedule: Create a comprehensive maintenance schedule for your gas detectors, including regular cleaning, inspection, and repair. This proactive approach safeguards the detector’s longevity and ensures optimal performance throughout its lifespan.

FAQs

Q: How often should I calibrate my XNX gas detector?

The calibration frequency depends on the specific model and the environment in which it is used. However, a general rule of thumb is to calibrate at least annually or more frequently if the detector is exposed to harsh conditions or is used frequently.

Q: What should I do if my gas detector fails calibration?

If a gas detector fails calibration, it means it is not providing accurate readings. Contact the manufacturer or a qualified technician to diagnose and repair the detector. Do not attempt to repair the detector yourself unless you are a trained professional.

Q: What are the consequences of not calibrating my gas detector?

Failing to calibrate your gas detector can result in inaccurate readings, leading to potential risks: False alarms, missed dangerous gas levels, and compromised safety for workers.

Xnx Gas Detector Calibration 2022 Pdf

Conclusion

The XNX gas detector calibration 2022 PDF is a vital resource for ensuring the accuracy and safety of your gas detection equipment. By diligently following the instructions outlined in this document, you can maintain a safe working environment for your employees, minimize potential accidents, and ensure compliance with industry standards.

Are you interested in learning more about gas detector calibration and how to ensure the safety of your workplace? Let us know in the comments below!